Page 114 - Vol.43

P. 114

Tech

Notes

技術專文

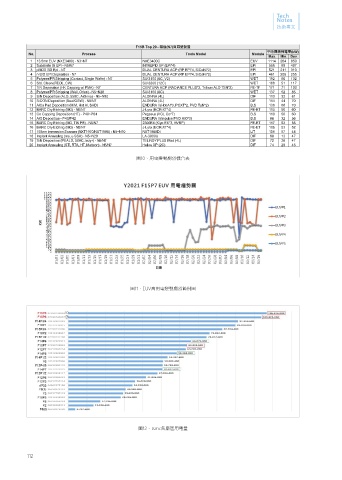

F15B Top 20 - 機台(N7)負載變動量

平時運轉用電量(kW)

No. Process Tools Model Module

Max. Min. Dev.

1 13.5nm EUV (NXE3400) - N3~N7 NXE3400C EUV 1114 264 850

2 Substrate Si EPI - N5/N7 INTREPID XP (EPI*4) EPI 556 69 487

3 pMOS SD Epi - N7 DUAL CENTURA ACP (RP EPI*4, SiCoNi*2) EPI 521 211 310

4 n-S/D EPI Deposition - N7 DUAL CENTURA ACP (RP EPI*4, SiCoNi*2) EPI 461 206 255

5 Polymer/PR Stripping (Contact, Single Wafer) - N7 SU-3100 (8C, V2) WET 192 60 132

6 Std. Clean (FEOL, CW) SU-3200 (12C) WET 168 51 117

7 TiN Deposition (HK Capping w/ PMA) - N7 CENTURA ACP (RADIANCE PLUS*2, Trillium ALD TSN*2) FE-TF 171 71 100

8 Polymer/PR Stripping (Well, Orion) - N5~N28 SU-3100 (8C) WET 137 52 85

9 SiN Deposition (ALD, 550C, Aldinna) - N5~N10 ALDINNA (4L) DIF 113 32 81

10 SiCON Deposition (Seal/OSW) - N5/N7 ALDINNA (4L) DIF 114 44 70

11 AlCu Pad Deposition (MiM, Hot Al, SHD) ENDURA II (Hot Al*3, PCXT*2, PVD TaN*2) B.S 136 66 70

12 BARC Dry Etching (MG) - N5/N7 J-Lynx (ECR-XT*4) FE-ET 110 50 60

13 Co Capping Deposition (HT) - P40~P64 Pegasus (VOL Co*7) B.S 110 50 60

14 AlO Deposition - P40/P42 ENDURA II (Impulse PVD AlO*3) B.S 88 32 56

15 BARC Dry Etching (MG, TiN PB) - N5/N7 2300E4 (Kiyo EX*3, HVBP) FE-ET 117 62 55

16 BARC Dry Etching (MG) - N5/N7 J-Lynx (ECR-XT*4) FE-ET 106 53 52

17 193nm Immersion Scanner (NXT1970/NXT1980) - N5~N10 NXT1980Di LIT 105 57 48

18 Implant Annealing (ms, u-SSA) - N5~N20 LA-3000U DIF 60 13 47

19 SiN Deposition (PEALD, 500C, Indy+) - N5/N7 TELINDY PLUS IRad (4L) DIF 72 26 47

20 Implant Annealing (STI, RTA, HT, Mattson) - N5/N7 Helios XP (2C) DIF 74 29 45

圖10、用電變動劇烈機台表

圖11、EUV高用電變動劇烈範例圖

圖12、tsmc各廠區用電量

112