Page 73 - Vol.13

P. 73

laser sensor to an image camera. The

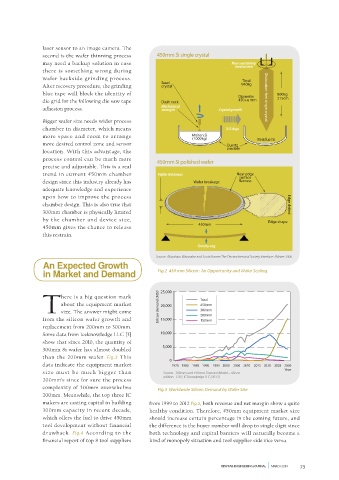

second is the wafer thinning process 450mm Si single crystal

may need a backup solution in case New sustaining

mechanism

there is something wrong during

wafer backside grinding process.

Seed Total

After recovery procedure, the grinding crystal 940kg

blue tape will block the identity of 800kg

Diameter Dislocation-free single crystal

die grid for the following die saw tape Dash neck 450+α mm 215cm

Mechanical

adhesion process. strength Crystal growth

Bigger wafer size needs wider process

chamber in diameter, which means 3-5 days

more space and room to arrange Molten Si Residual Si

(1000kg)

more desired control zone and sensor Quartz

location. With this advantage, the crucible

process control can be much more 450mm Si polished wafer

precise and adjustable. This is a real

trend in current 450mm chamber Wafer thickness Near edge

surface

design since this industry already has Wafer breakage atness

adequate knowledge and experience

upon how to improve the process

chamber design. This is also true that Edge defect

300mm chamber is physically limited

by the chamber and device size, Edge shape

450mm

450mm gives the chance to release

this restrain.

Gravity sag

Source. Masaharu Watanabe and Scott Kramer The Electrochemical Society Interface • Winter 2006

An Expected Growth

in Market and Demand Fig.2 450 mm Silicon : An Opportunity and Wafer Scaling.

here is a big question mark 25,000 Total

about the equipment market Silicon demand (MSI) 20,000 450mm

Tsize. The answer might come 300mm

200mm

from the silicon wafer growth and 15,000 150mm

replacement from 200mm to 300mm.

Some data from Iceknowledge LLC [3] 10,000

show that since 2010, the quantity of

5,000

300mm Si wafer has almost doubled

than the 200mm wafer. Fig.3 This

0

data indicate the equipment market 1975 1980 1985 1990 1995 2000 2005 2010 2015 2020 2025 2030

Year

size must be much bigger than Source. 300mm and 450mm Forecast Model – silicon

edition -1202, IC Knowledge LLC (2012)

200mm’s since for sure the process

complexity of 300mm overwhelms Fig.3 Worldwide Silicon Demand by Wafer Size

200mm. Meanwhile, the top three IC

makers are casting capital in building from 1999 to 2012 Fig.5, both revenue and net margin show a quite

300mm capacity in recent decade, healthy condition. Therefore, 450mm equipment market size

which offers the fuel to drive 450mm should increase certain percentage in the coming future, and

tool development without financial the difference is the buyer number will drop to single digit since

drawback. Fig.4 According to the both technology and capital barriers will naturally become a

financial report of top 8 tool suppliers kind of monopoly situation and tool supplier side vice versa.

NEW FAB ENGINEERING JOURNAL MARCH 2014 73