Page 75 - Vol.13

P. 75

M USD Net Income Revenue

45,000

40,000

35,000

30,000

25,000

20,000

15,000

10,000

5,000

0

1999 2000 2001 2010 2011 2012

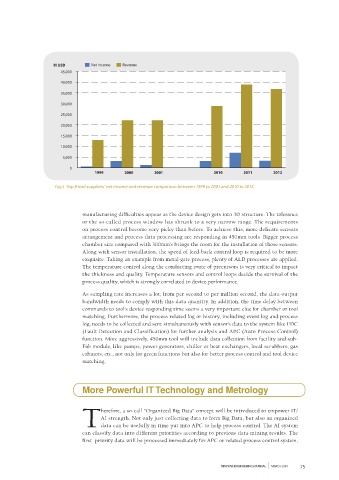

Fig.5 Top 8 tool suppliers’ net income and revenue comparison between 1999 to 2001 and 2010 to 2012.

manufacturing difficulties appear as the device design gets into 3D structure. The tolerance

or the so-called process window has shrunk to a very narrow range. The requirements

on process control become very picky than before. To achieve this, more delicate sensors

arrangement and process data processing are responding in 450mm tools. Bigger process

chamber size compared with 300mm’s brings the room for the installation of those sensors.

Along with sensor installation, the speed of feed-back control loop is required to be more

exquisite. Taking an example from metal-gate process, plenty of ALD processes are applied.

The temperature control along the conducting route of precursors is very critical to impact

the thickness and quality. Temperature sensors and control loops decide the survival of the

process quality, which is strongly correlated to device performance.

As sampling rate increases a lot, from per second to per million second, the data-output

bandwidth needs to comply with this data quantity. In addition, the time delay between

commands to tool’s device responding time seems a very important clue for chamber or tool

matching. Furthermore, the process related log or history, including event log and process

log, needs to be collected and sent simultaneously with sensor’s data to the system like FDC

(Fault Detection and Classification) for further analysis and APC (Auto Process Control)

function. More aggressively, 450mm tool will include data collection from facility and sub-

Fab module, like pumps, power generators, chiller or heat exchangers, local scrubbers, gas

cabinets, etc., not only for green functions but also for better process control and tool device

matching.

More Powerful IT Technology and Metrology

herefore, a so-call “Organized Big Data” concept will be introduced to empower IT/

AI strength. Not only just collecting data to form Big Data, but also an organized

Tdata can be usefully in time put into APC to help process control. The AI system

can classify data into different priorities according to previous data-mining results. The

first priority data will be processed immediately for APC or related process control system,

NEW FAB ENGINEERING JOURNAL MARCH 2014 75