Page 106 - Vol.24

P. 106

New

Vision

新象新知

Boundary condition

Advanced Source Valve Advanced Sink

12CHS01 TCV02 12CHR01

S_OUT S_IN S_OUT S_IN #10 Process Stream

#8 VALVE_POS

#9 Sink – cooling

Valve Advanced Sink

TCV01 35WWR01 water and air

Advanced Source S_IN S_OUT S_IN

35WWS01 VALVE_POS #5

S_OUT #4

#3

Pre-heating CLC-1 Pre-cooling

Dyn HX (Tube/Shel l) Stream Input Vessel Advanced Sink

HTC-1 STR_CLC-1_VAP_OUT CLC-1_VAP SNK_ARW01

T_S_IN T_S_OUT S_OUT S_IN_1 S_OUT_1 S_IN

S_S_OUT

Advanced Source Valve S_S_IN IN_TUBE_TEMP #11 VESSEL_PRESS -1067 #14

SRC_OSA01 SD01 OUT_TUBE_TEMP S_P7F4MAU206_CLC-1/STR_CLC-1_VAP_OUT VESSEL_TEMP

S_OUT S_IN S_OUT IN_SHELL_TEMP -967 Pag #13

-425 Pag #1 VALVE_POS OUT_SHELL_TEMP Advanced Sink

#2 #6 SNK_CLC-1

S_IN

-967 Pag #7

Stream Input Advanced Sink

STR_CLC-1_LIQ_OUT SNK_WD01

S_OUT S_IN Elevation

below by 2m

#12 #15

S_P7F4MAU206_CLC-1/STR_CLC-1_LIQ_OUT

Advanced Source Valve Vessel Pump

SRC_DIW LCV01 VSL_DIW AW-P ARW Air-washer

S_OUT S_IN S_OUT S_IN_1 S_OUT_1 S_IN S_OUT

#16 VALVE_POS VESSEL_PRESS VOL_FLOW Advanced Sink

#17 VESSEL_TEMP MASS_FLOW SNK_ARW02 Elevated by

#18 POWER S_IN 10m

#19

#20

Elevation Stream Input Vessel

below by 2m STR_ARW_OUT ARW_VAP

S_OUT S_IN_1 S_OUT_1

#21 VESSEL_PRESS

S_P7F4MAU206_ARW/STR_ARW_OUT VESSEL_TEMP

-1067 Pag #22

CLC-1 Cooling

Heating

Stream Input Vessel

Valve

STR_CLC-2_VAP_OUT CLC-2_VAP Dyn HX (Tube/Shell) TCV04 Advanced Sink

HTC-2

35WWR02

S_OUT S_IN_1 S_OUT_1 T_S_IN T_S_OUT S_IN S_OUT S_IN

#27 VESSEL_PRESS

VESSEL_TEMP S_S_IN S_S_OUT Valve VALVE_POS #33

IN_TUBE_TEMP

S_P7F4MAU206_CLC-2/STR_CLC-2_VAP_OUT -1326 Pag #28 OUT_TUBE_TEMP PSEUDO_VLV01 #32

Advanced Sink IN_SHELL_TEMP S_IN S_OUT

SNK_CLC-2 OUT_SHELL_TEMP

S_IN #34 VALVE_POS #35

-1326 Pag #23

Valve Advanced Sink

Stream Input SD02 SNK_LIT

STR_CLC-2_LIQ_OUT -1370 Pag 2676 Pag S_IN S_OUT S_IN

S_OUT Compressor Vessel VALVE_POS #40

#29 FND DUCT01 #38

S_P7F4MAU206_CLC-2/STR_CLC-2_LIQ_OUT S_IN S_OUT S_IN_1 S_OUT_1

VOL_FLOW S_OUT_2

MASS_FLOW S_OUT_3

POWER S_OUT_4 Valve Advanced Sink

Advanced Source #36 389 Pag VESSEL_PRESS SD03 SNK_PURGE

35WWS02 VESSEL_TEMP S_IN S_OUT S_IN

S_OUT Fan #37 VALVE_POS #41

#31 #39

Process Stream Source for Advanced Sink

SNK_WD02

hot water S_IN #30 Elevation

below by 2m

Advanced Source Valve Advanced Sink

5CHS01 TCV03 5CHR01

S_OUT S_IN S_OUT S_IN

#24 VALVE_POS #26

#25

Process Stream Source for cooling water Process Stream Sink – Air

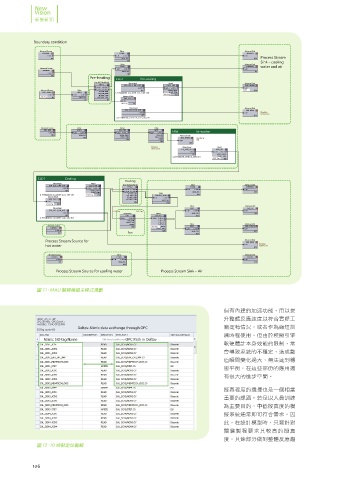

圖 11、MAU 製程模組主程式規劃

俱有內建的加速功能,用以提

升整體反應速度以符合實際工

Deltav-Mimic data exchange through OPC 廠運轉情況,或者作為縮短訓

練時程使用,但由於模擬引擎

Mimic SIO tag Name OPC Path in Deltav

軟硬體計本身效能的限制,常

會導致系統的不穩定,造成數

值瞬間變化過大,無法達到穩

態平衡,在這些部份的應用還

有很大的進步空間。

擬真程度的選擇也是一個相當

重要的課題。若是以人員訓練

為主要目的,中低擬真度的模

擬系統通常即可符合需求。因

此,在設計模型時,只要針對

關鍵製程要求其較高的擬真

度,其餘部分做到整體反應趨

圖 12、IO 映射定址編輯

106