Page 65 - Vol.43

P. 65

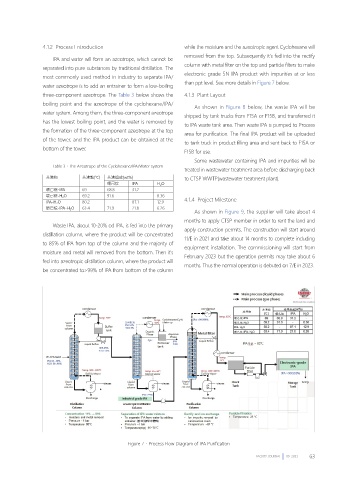

4.1.2 Process I ntroduction while the moisture and the azeotropic agent Cyclohexane will

removed from the top. Subsequently it's fed into the rectify

IPA and water will form an azeotrope, which cannot be

column with metal filter on the top and particle filters to make

separated into pure substances by traditional distillation. The

electronic grade 5N IPA product with impurities at or less

most commonly used method in industry to separate IPA/

than ppt level. See more details in Figure 7 below.

water azeotrope is to add an entrainer to form a low-boiling

three-component azeotrope. The Table 3 below shows the 4.1.3 Plant Layout

boiling point and the azeotrope of the cyclohexane/IPA/

As shown in Figure 8 below, the waste IPA will be

water system. Among them, the three-component azeotrope

shipped by tank trucks from F15A or F15B, and transferred it

has the lowest boiling point, and the water is removed by

to IPA waste tank area. Then waste IPA is pumped to Process

the formation of the three-component azeotrope at the top

area for purification. The final IPA product will be uploaded

of the tower, and the IPA product can be obtained at the

to tank truck in product filling area and sent back to F15A or

bottom of the tower.

F15B for use.

Some wastewater containing IPA and impurities will be

Table 3、The Azeotrope of the Cyclohexane/IPA/Water system

treated in wastewater treatment area before discharging back

共沸物 共沸點(℃) 共沸組成(wt%) to CTSP WWTP(wastewater treatment plant).

環已烷 IPA H 2 O

環已烷-IPA 69 68.8 31.2

環已烷-H 2 O 69.2 91.6 8.36 4.1.4 Project Milestone

IPA-H 2 O 80.2 87.1 12.9

環已烷-IPA-H 2 O 63.4 71.9 21.8 6.26

As shown in Figure 9, the supplier will take about 4

months to apply CTSP member in order to rent the land and

Waste IPA, about 10-20% od IPA, is fed into the primary

apply construction permits. The construction will start around

distillation column, where the product will be concentrated

11/E in 2021 and take about 14 months to complete including

to 85% of IPA from top of the column and the majority of

equipment installation. The commissioning will start from

moisture and metal will removed from the bottom. Then it's

February 2023 but the operation permits may take about 6

fed into azeotropic distillation column, where the product will

months. Thus the normal operation is debuted on 7/E in 2023.

be concentrated to>99% of IPA from bottom of the column

Figure 7、Process Flow Diagram of IPA Purification

FACILITY JOURNAL 09 2021 63