Page 68 - Vol.43

P. 68

Tech

Notes

技術專文

Figure 12、Project Milestones of ARP Scope

Table 4、The Typical Concentration and Impurities of Waste H 2 SO 4 Feed. Then it's fed into evaporation column under 220℃ and 0.4bar

Assay_H 2 SO 4 : 45~60% pressure to thermally decompose H 2 SO 4 to SO 3 and water.

Assay_H 2 O 2 <10% Subsequently SO 3 vapor is fed into the adsorption tower

Fluoride<0.1%

Chloride<0.1% absorbed by H 2 SO 4 to produce H 2 S 2 O 7 . And then it produces

Nitrate<0.1% high-purity H 2 SO 4 through hydrolysis. The chemical reaction

total metal<0.1% equations inside adsorption tower are shown as below.

organic compounds<1%

Water : balanced

SO 3 vapor is absorbed into oleum by sulfuric acid.

4.3.2 Process Introduction SO 3(g) +H 2 SO 4(l) → H 2 S 2 O 7(l)

Sulfuric acid regeneration technology mainly adapts Hydrolysis

vacuum pressure cryogenic distillation under vacuum pressure H 2 S 2 O 7(l) +H 2 O (l) → 2H 2 SO 4(l)

with the quartz distillation tower supported by SS316 under

multi-stage temperature conditions to removes hydrogen Then it removes particle through the series of particle

peroxide, water and impurities. filters to make final electronic grade H 2 SO 4 product with

Waste H 2 SO 4 , about 45-60% of H 2 SO 4 , is pre-heated by impurities less than 5ppt level. See the process flow diagram in

waste heat exchanger and fed into the series of the distillation Figure 13 below.

column #1 and #2 to remove H 2 O 2 , water and impurities.

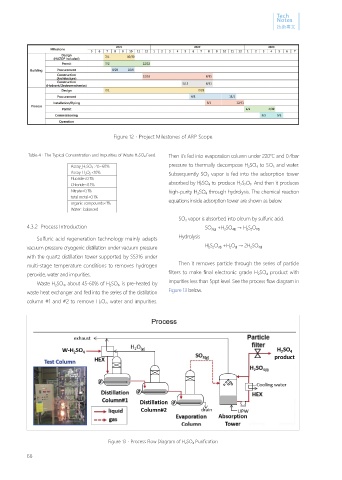

Figure 13、Process Flow Diagram of H 2 SO 4 Purification

66