Page 75 - Vol.43

P. 75

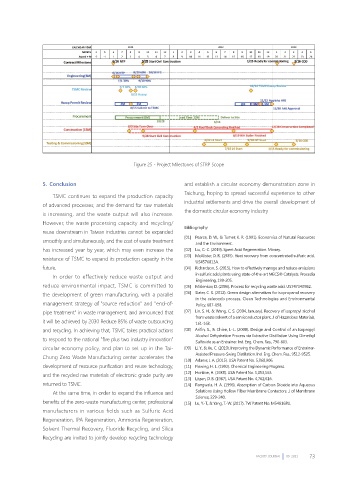

Figure 25、Project Milestones of STRP Scope

5. Conclusion and establish a circular economy demonstration zone in

Taichung, hoping to spread successful experience to other

TSMC continues to expand the production capacity

industrial settlements and drive the overall development of

of advanced processes, and the demand for raw materials

the domestic circular economy industry

is increasing, and the waste output will also increase.

However, the waste processing capacity and recycling/

Bibliography

reuse downstream in Taiwan industries cannot be expanded

[01] Pearce, D. W., & Turner, K. R. (1991). Economics of Natural Resources

smoothly and simultaneously, and the cost of waste treatment

and the Environment.

has increased year by year, which may even increase the [02] Liu, C.-C. (2019). Spent Acid Regeneration. Money.

[03] McAlister, D. R. (1985). Heat recovery from concentrated sulfuric acid.

resistance of TSMC to expand its production capacity in the

US4576813A.

future. [04] Richardson, S. (2015). How to effectively manage and reduce emissions

In order to effectively reduce waste output and in sulfuric acid plants using state-of-the-art MECS® Catalysts. Procedia

Engineering, 199-205.

reduce environmental impact, TSMC is committed to [05] Mislenkov, D. (2006). Process for recycling waste acid. US7473409B2.

the development of green manufacturing, with a parallel [06] Slater, C. S. (2012). Green design alternatives for isopropanol recovery

in the celecoxib process. Clean Technologies and Environmental

management strategy of "source reduction" and "end-of- Policy, 687-698.

pipe treatment" in waste management, and announced that [07] Lin, S. H., & Wang, C. S. (2004, January). Recovery of isopropyl alcohol

from waste solvent of a semiconductor plant. J. of Hazardous Materials,

it will be achieved by 2030 Reduce 85% of waste outsourcing 161-168.

and recycling. In achieving that, TSMC takes practical actions [08] Arifin, S., & Chien, I.-L. (2008). Design and Control of an Isopropyl

Alcohol Dehydration Process via Extractive Distillation Using Dimethyl

to respond to the national "five plus two industry innovation"

Sulfoxide as an Entrainer. Ind. Eng. Chem. Res., 790-803.

circular economy policy, and plan to set up in the Tai- [09] Li, Y., & Xu, C. (2019). Improving the Dynamic Performance of Entrainer-

Assisted Pressure-Swing Distillation. Ind. Eng. Chem. Res., 9512-9525.

Chung Zero Waste Manufacturing center accelerates the

[10] Adams, J. A. (2015). USA Patent No. 5,868,906.

development of resource purification and reuse technology, [11] Flewing, H. L. (1992). Chemical Engineering Progress.

and the recycled raw materials of electronic grade purity are [12] Horizoe, H. (1988). USA Patent No. 5,053,563.

[13] Litzen, D. B. (1987). USA Patent No. 4,762,616.

returned to TSMC. [14] Rangwala, H. A. (1996). Absorption of Carbon Dioxide into Aqueous

At the same time, in order to expand the influence and Solutions Using Hollow Filber Membrane Contactors. J. of Membrane

Science, 229-240.

benefits of the zero-waste manufacturing center, professional [15] Lu, Y.-T., & Yang, T.-W. (2017). TW Patent No. M548168U.

manufacturers in various fields such as Sulfuric Acid

Regeneration, IPA Regeneration, Ammonia Regeneration,

Solvent Thermal Recovery, Fluoride Recycling, and Silica

Recycling are invited to jointly develop recycling technology

FACILITY JOURNAL 09 2021 73