Page 75 - Vol.15

P. 75

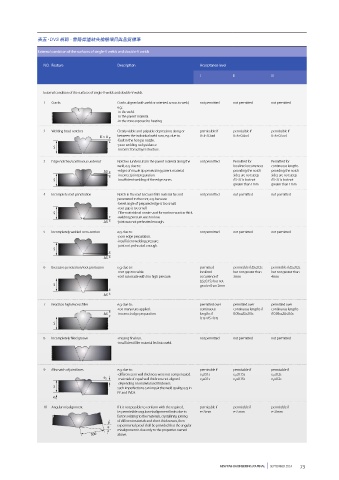

表五、DVS 規範 - 管路焊道缺失檢驗項目與品質標準

External condition of the surfaces of single-V welds and double-V welds

NO. Feature Description Acceptance level

I II III

External condition of the surfaces of single-V welds and double-V welds

1 Cracks Cracks aligned with weld or oriented across to weld, not permitted not permitted not permitted

e.g.:

-in the weld.

-in the parent material.

-in the zone exposed to heating.

2 Welding bead notches Clearly visible and palpable depressions along or permissible if permissible if permissible if

K > 0 between the individual weld runs, e.g. due to: 0<k≤0.3×d 0<k≤0.4×d 0<k≤0.5×d

-fault in the hot gas nozzle.

-poor welding rod guidance.

S

-incorrect bead layer structure.

3 Edge notches/continuous undercut Notches (undercuts) in the parent material along the not permitted Permitted for Permitted for

weld, e.g. due to: localized occurrences continuous lengths

S -edges of nozzle tip penetrating parent material. providing the notch providing the notch

-incorrect joint preparation. sides are not steep sides are not steep

S -insufficient welding of the edge zones. ∆S≤0.1s but not ∆S≤0.1s but not

greater than 1mm greater than 1mm

4 Incomplete root penetration Notch in the root because filler material has not not permitted not permitted not permitted

penetrated to the root, e.g. because:

-bevel angle of prepared edge is too small.

-root gap is too small.

S Filler material rod or wire used for root run was too thick.

-welding pressure was too low.

S -joint was not preheated enough.

5 Incompletely welded cross-section e.g. due to: not permitted not permitted not permitted

-poor edge preparation.

-insufficient welding pressure.

-joint not preheated enough.

S

S

6 Excessive penetration/root protrusion e.g. due to: permitted permissble if ∆S≤0.2s permissble if ∆S≤0.2s

-root gap too wide. localized but not greater than but not greater than

-root run made with too high pressure. occurrence if 3mm 4mm

∆S≤0.15s but not

S greater than 2mm

S

7 Bead too high/excess filler e.g. due to: permitted over permitted over permitted over

-too many runs applied. continuous continuous lengths if continuous lengths

S -incorrect edge preparation. lengths if 0.05s≤∆S≤0.5s if 0.05s≤∆S≤0.6s

0.1s≤∆S≤0.4s

S

8 Incompletely filled groove -missing final run. not permitted not permitted not permitted

-insufficient filler material fed into weld.

9 Mismatch of joint faces e.g. due to: permissble if permissble if permissble if

-differences in wall thickness were not compensated. e 1 ≤0.1s e 1 ≤0.15s e 1 ≤0.2s

e 2 -materials of equal wall thickness not aligned. e 2 ≤0.1s e 2 ≤0.15s e 2 ≤0.2s

-depending on material and thickness:

S such imperfections can impair the weld quality, e.g. in

PP and PVDF.

e 1

10 Angular misalignment If it is not possible to conform with the required, permissble if permissble if permissble if

i.e. permissible angular misalignment limits due to e≤3mm e≤5mm e≤8mm

factors relating to the materials, crystallinity, joining

of different materials and sheet thicknesses, then

e experimental proof shall be provided that the angular

misalignment is due only to the properties named

300 above.

NEW FAB ENGINEERING JOURNAL SEPTEMBER 2014 73