Page 47 - Vol.43

P. 47

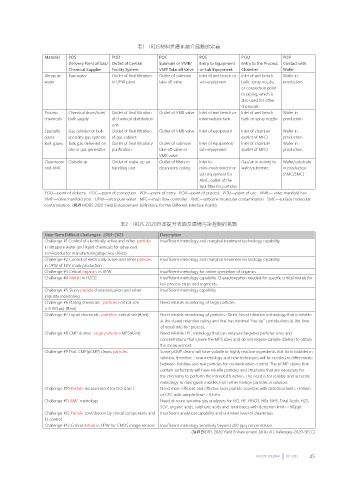

表1、IRDS材料供應系統介面點的定義

Material POS POD POC POE POU POP

Delivery Point of Gas/ Outlet of Central Submain or VMB/ Entry to Equipment Entry to the Process Contact with

Chemical Supplier Facility System VMP Take off Valve or Sub Equipment Chamber Wafer

Ultrapure Raw water Outlet of final filtration Outlet of submain Inlet of wet bench or Inlet of wet bench Wafer in

water in UPW plant take off valve sub-equipment bath, spray nozzle, production

or connection point

to piping, which is

also used for other

chemicals

Process Chemical drum/tote/ Outlet of final filtration Outlet of VMB valve Inlet of wet bench or Inlet of wet bench Wafer in

chemicals bulk supply of chemical distribution intermediate tank bath or spray nozzle production

unit

Specialty Gas cylinder or bulk Outlet of final filtration Outlet of VMB valve Inlet of equipment Inlet of chamber Wafer in

gases specialty gas systems of gas cabinet (outlet of MFC) production

Bulk gases Bulk gas delivered on Outlet of final filtration/ Outlet of submain Inlet of equipment/ Inlet of chamber Wafer in

site or gas generator purification take off valve or sub-equipment (outlet of MFC) production

VMB valve

Cleanroom Outside air Outlet of make-up air Outlet of filters in Inlet to Gas/air in vicinity to Wafer/substrate

and AMC handling unit cleanroom ceiling mini-environment or wafer/substrate in production

sub equipment for (AMC/SMC)

AMC, outlet of the

tool filter for particles

POD—point of delivery POC—point of connection POE—point of entry POP—point of process POU—point of use VMB— valve manifold box

VMP—valve manifold post UPW—ultra pure water MFC—mass flow controller AMC—airborne molecular contamination SMC—surface molecular

contamination (摘錄自IDRS 2020 Yield Enhancement Definitions for the Different Interface Points)

表2、IRDS 2020良率提升表面及環境污染控制的挑戰

Near-Term Difficult Challenges : 2019–2023 Description

Challenge #1 Control of electrically active and other particles Insufficient metrology and marginal treatment technology capability

in ultrapure water and liquid chemicals for advanced

semiconductor manufacturing(logic key driver)

Challenge #2 Control of electrically active and other particles Insufficient metrology and marginal treatment technology capability

in UPW of EUV mask production

Challenge #3 Critical organics in UPW Insufficient metrology for online speciation of organics

Challenge #4 Metals in H2O2 Insufficient metrology capability. Characterization needed for specific critical metals for

key process steps and segments.

Challenge #5 Slurry particle characterization and other Insufficient metrology capability

impurity monitoring

Challenge #6 Plating chemicals : particles>critical size Need reliable monitoring of large particles

(>0.150um) (#/ml)

Challenge #7 Liquid chemicals : particles>critical size(#/ml) Need reliable monitoring of particles<10nm. Need Filtration technology that is reliable

at the stated retention rating and that has minimal "rise up" contributions at the time

of install into the process.

Challenge #8 CMP slurries : large particles>MPS(#/ml) Need reliable LPC metrology that can measure targeted particles sizes and

concentrations that ignore the MPS sizes and do not require sample dilution to obtain

the measurement.

Challenge #9 Post-CMP(pCMP) cleans particles Some pCMP cleans will have volatile or highly reactive ingredients that form bubbles in

solution, therefore ; new metrology and new techniques will be needed to differentiate

between bubbles and real particles for contamination control. The pCMP cleans that

contain surfactants will have micelle particles and structures that are necessary for

the chemistry to perform the intended function. The need is for reliable and accurate

metrology to distinguish micelles from other foreign particles in solution.

Challenge #10 Particle measurement for ISO class 1 Need more efficient and effective laser particle counters with detection limit<<100nm

or CPC with sample flow>>0,1cfm

Challenge #11 AMC metrology Need of more sensitive gas analyzers for HCl, HF, HNO3, HBr, NH3, Total Acids, H2S,

SO2, organic acids, sulphuric acids and Total bases with detection limit<<100ppt

Challenge #12 Particle contribution by critical components and Insufficient analytical capability and unknown level of cleanliness

its control

Challenge #13 Critical metals in UPW for CMOS image sensors Insufficient metrology sensitivity beyond 200 ppq concentration

(摘錄自IDRS 2020 Yield Enhancement Difficult Challenges-2020-SECC)

FACILITY JOURNAL 09 2021 45